The Future of the Footwear Industry?

Shoe designs have come a long way, from the early days of sandals and moccasins to modern-day sneakers and flip flops. Now we are entering into the era of 3D-printed shoes.

3D printing is used in many industries, and the footwear industry is one of the beneficiaries. Unlike other methods, 3D printing allows customization, offers a higher level of detail, and is often heavier than traditional shoes. But how does the printing process work?

How Shoes Are 3D Printed

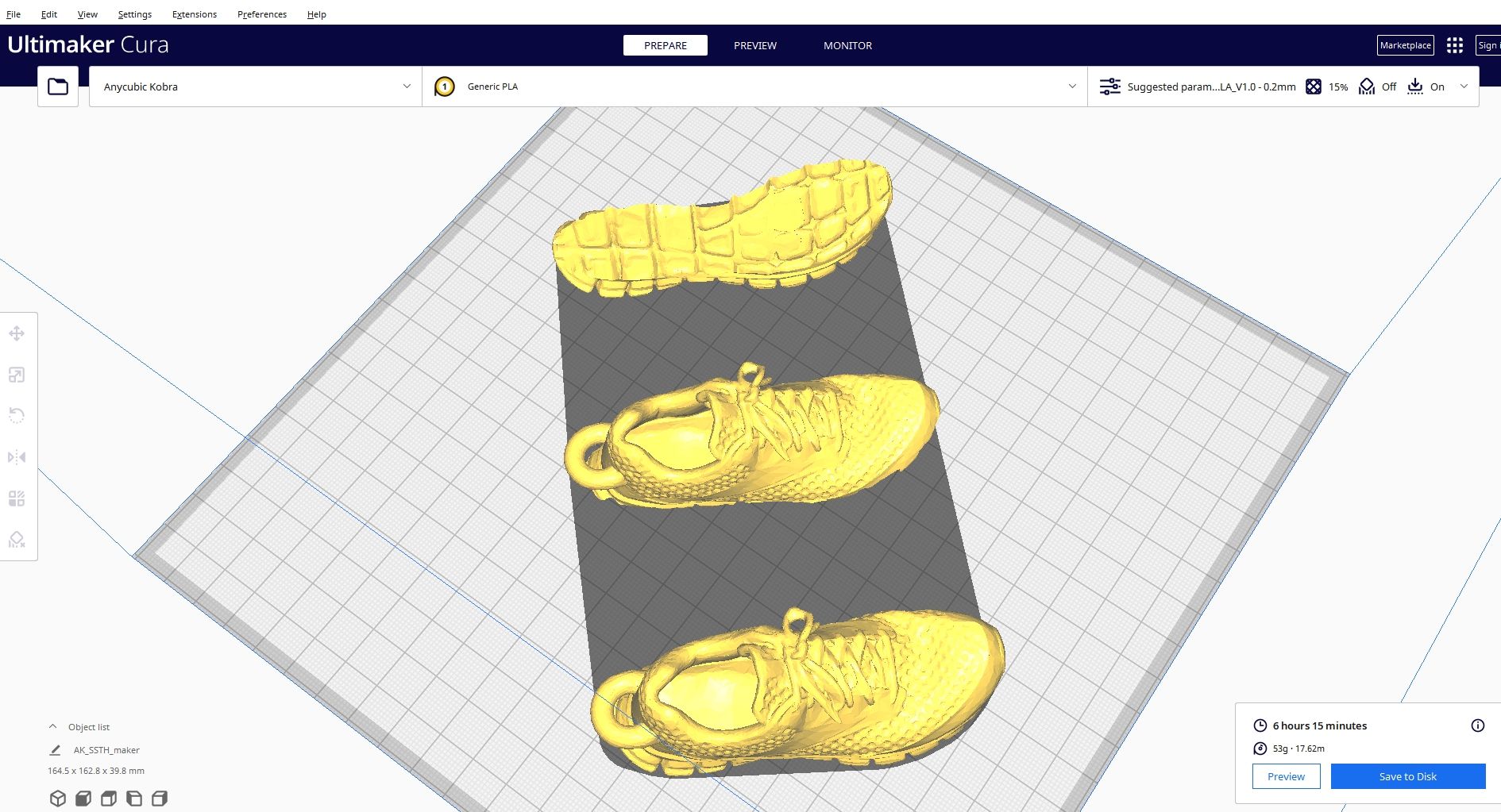

Like in 3D printing other designs, the process starts with creating a 3D file using 3D modeling software. In addition to designing the shoes from scratch, you can also download ready-to-print shoe models from various websites offering free 3d printing files like Thingiverse, Myminifactory, Printables, and Cults3D.

After the design process, the next step is to convert the model into a format that a 3D printer understands known as the G-code.

The G-code contains instructions the 3D printer can follow to convert the digital file into a physical model. You can then send the file to your 3D printer and start 3D printing. Below is a sample of a 3D printed sneaker.

There are various materials that you can use to 3D print shoes, and one of them is TPU. TPU is ideal for 3D printing shoes as it’s inexpensive, flexible, highly elastic, and durable, making it helpful in running and high-end shoes.

Nylon is another material that is commonly used in shoe 3D printing as it’s strong and durable at the same time. It is also lightweight and resistant to wear and tear.

Companies That Offer 3D Printed Shoes

Having looked at how shoes are 3D printed, let’s go deeper and look at some companies utilizing 3D printing to create shoes.

1. Adidas

Adidas is utilizing 3D printing to innovate and develop new shoe designs. As posted on the Adidas website, the company ventured into 3D printing for the first time in 2015 when it launched its Futurecraft 3D concept, which focused on using 3D printing technology to create running shoes. The goal of the initiative was that in the future, one could walk into an Adidas shop and have their gait and feet analyzed by foot scanning technology and, after that, a 3D printed shoe made specifically for you within a few minutes. Adidas partnered with Materialise, a Belgian technology company, to bring this idea to life.

After the Futurecraft 3D concept, Adidas launched its first 3D-printed shoe in late 2016, whose release is still detailed on the Adidas website. Since then, the company has continued advancing and launching new designs. In 2018, as covered by The Independent, the AlphaEdge 4D model version was launched. The midsoles were 3D printed using the Digital Light Synthesis process, and their upper part was made from woven fabric.

A newer design is the Adidas Ulta4D for running and streetwear. It’s black and white, and it glows in the dark.

The upper part of the shoe is 50% made from recycled polyester, and the midsole is the one that is 3D printed.

2. Reebok

Reebok is also tapping into 3D printing. After releasing a press release introducing the 3D drawing concept in the shoe design that uses robots and state-of-the-art software to draw shoes in 3D dimensions, it is now 3D printing them too.

The latest shoe Reebok 3D printed is the Liquid Floatride Run shoe that has “Flexweave” materials and liquid elements around it, which was covered by Digital Trends. The laces and stripes at the bottom are also fully 3D printed.

3. New Balance

New Balance collaborated with 3D Systems to 3D print the midsoles of its shoes using DuraForm Flex TPU and elastomeric powder materials. Selective Laser Sintering Process (SlS), a 3D printing technology that turns powders into solid objects, was used. Cushioning elements are added in the areas with higher average pressure.

In addition to the above well-known companies using 3D printing to create shoes, there are some inspirational 3D-printed shoes from a smaller player worth exploring.

FUSED footwear has been 3D printing shoes since 2017. All of the company’s shoes are 3D printed as one piece and can be worn just like regular shoes. Anyone can order them on the FUSED footwear website. You can choose your size and color, then proceed to pay.

You can choose from a wide range of comfortable and stylish shoes. The main feature of FUSED footwear is the fused sole technology, which promises to offer superior comfort, style, and durability. Fused sole technology creates a hybrid sole that combines the comfort of a running or walking shoe with the durability of a hiking boot, providing traction and cushioning. The shoes offer improved stability, comfort, and shock absorption.

Technologies for 3D Printing Shoes

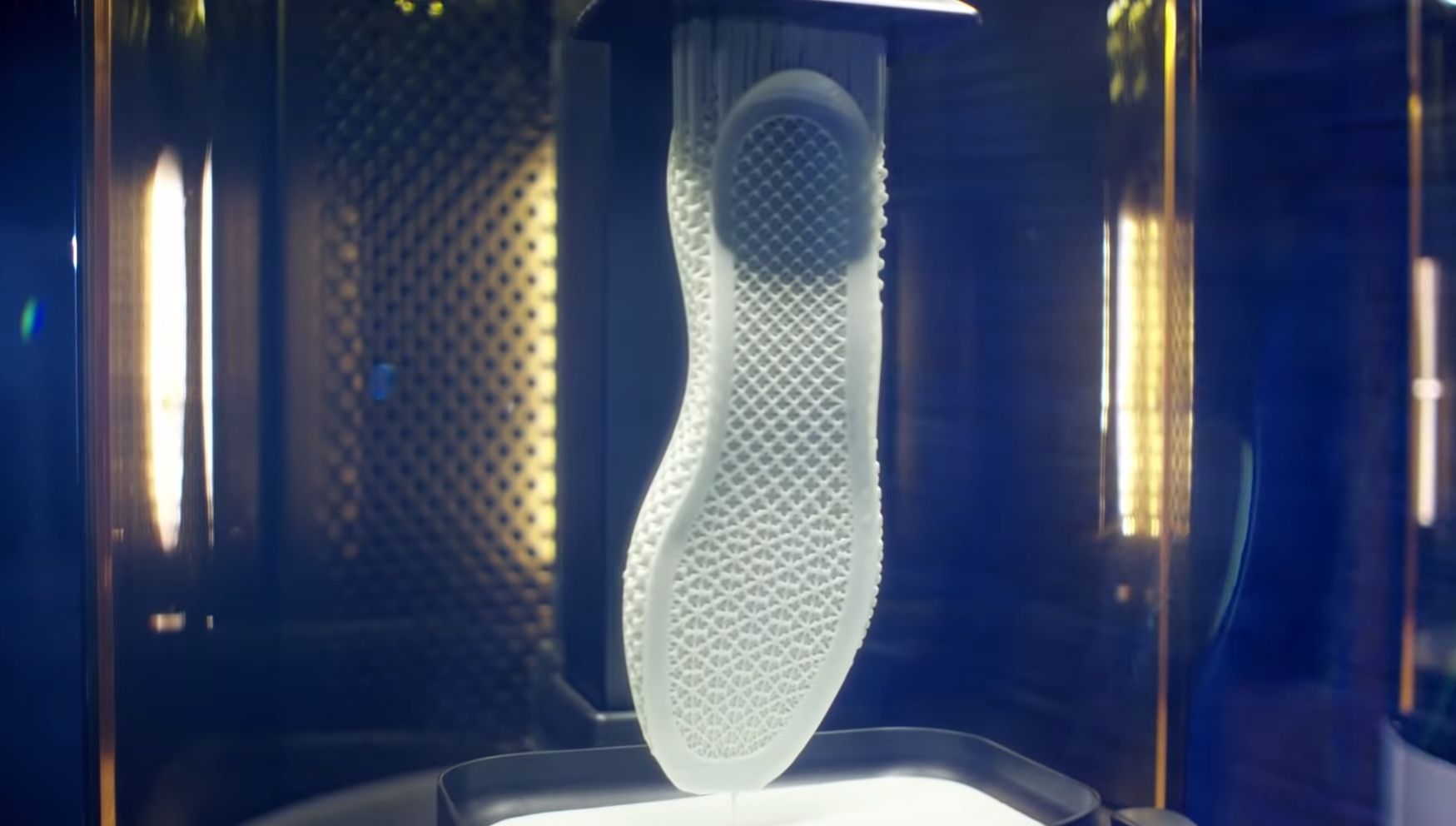

The 3D printing technology used in creating shoes depends on the 3D part printed and the materials available. Stereolithography is often used for printing shoe soles because it can create parts with smooth surfaces and complex and intricate designs that would be difficult or impossible to do using other methods.

The process uses a liquid resin and a light source to “cure” the resin layer by layer. The resin is cured using an ultraviolet laser, which is directed at the resin and solidifies it. The process repeats until the entire object of the shoe is formed.

The smooth surface finish SLA provides is ideal for shoe soles, which require a smooth and comfortable finish to ensure the wearer feels comfortable. The accuracy of the printing process also ensures that the sole fits the user’s foot well and that there is comfort.

Fused Deposition Modeling is another technology companies use in 3D printing shoes. Thermoplastic filaments like TPU are utilized in creating both the outer and soles of the shoes. It can be faster and more affordable than SLA but can produce less detailed prints. FDM is a good option for printing shoe soles that need to be functional but do not require a high level of detail.

Benefits of 3D Printing Shoes

You can use 3D printing to create shoes for the following use cases:

- Customization: You can create custom shoes tailored to the wearer’s foot shape and size. A 3D scanner is used to get the exact dimensions and structure of the foot and ensure the exact design is replicated.

- Lightweight shoes: With 3D printing, you can create shoes with lightweight materials like carbon fiber. Carbon fiber is a strong and lightweight material, and it is also highly durable and can withstand a lot of wear and tear.

- Eliminate costly prototyping: With 3D printing, you can adjust your design in a CAD program easily before sending it to your 3D printer, and any corrections required can be fixed quickly, saving the cost one would have incurred in changing your designs.

- Unique design elements: You can use 3D printing technology to add unique design elements to your shoes, such as decorative patterns and logos.

While we are still far from having fully 3D-printed shoes in our stores, this technology has made great strides since its invention.

As 3D printers become affordable and easily accessible, the future of this manufacturing method is promising, and 3D-printed shoes will become more commonplace.

link